Let’s look at the breathing cycle when a scuba diver breathes with a regulator and the pressure changes inside the second stage regulator.

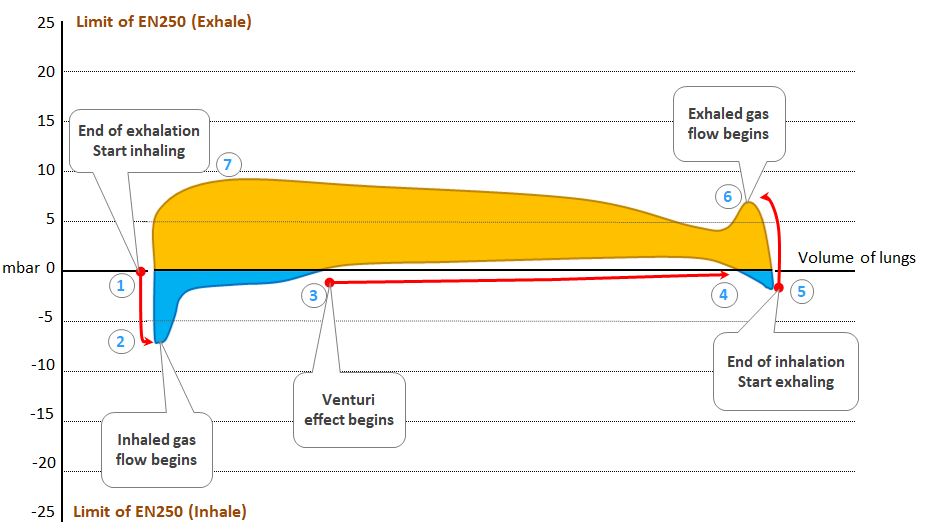

In the picture, the horizontal axis represents the volume of the lungs, and as it expands to the right, the volume of the lungs increases. The vertical axis shows the pressure change inside the second stage regulator, with the pressure inside the regulator being 0 in the middle, positive pressure at the top, and negative pressure at the bottom.

In the figure, 1 is the point at which the diver feels the urge to breathe and begins to breathe, with the lung volume at a minimum during that breathing cycle.

The low-pressure seat of the second stage regulator is always pressed against the orifice by the elasticity of the spring, preventing air from flowing out. However, if the diver inhales air with a force greater than the elasticity of the spring, the orifice moves back, widening the gap with the low pressure sheet, and the air waiting in the first stage of the regulator flows in.

Like this, the pressure inside the second stage regulator when the orifice moves backwards and separates from the low pressure sheet is called cracking pressure, and because the diver is inhaling air, it has a negative pressure value as shown in the graph. This point is number 2 on the graph, and when the gas begins to flow, the negative pressure value inside the regulator decreases due to the increased flow rate and fluid pressure.

The pressure inside the second stage regulator must be kept negative by continuing to inhale air until the diver finishes inhaling, but the pressure inside the regulator may change to a positive value as shown between 3 and 4 in the graph.

When a regulator designed to utilize the Venturi effect is used in the second stage regulator, the air flow inside the second stage regulator is changed so that air continues to flow in due to the Venturi effect even if the diver does not inhale air.

When the diver has inhaled enough air, the inhalation ends when point 5 is reached.

For exhalation, even if the diver exhales at point 5 in the table, air is not released until a certain amount of pressure rises within the regulator. However, when the expiratory pressure reaches point 6 in the table, which is greater than the ambient pressure pushing on the exhaust valve diaphragm, the exhaust valve diaphragm opens and the expiratory airflow begins.

The moment the exhaust valve diaphragm opens, the positive pressure inside drops a little, but as the diver continues to blow out more air than is expelled, the positive pressure rises higher and reaches point 7 in the table.

Finally, when the diver stops exhaling for the next breath, point 1 in the table is reached and one cycle of breathing is completed.

Everyone knows the breathing cycle, but there are a few things we need to think about here.

In order to breathe comfortably, the feeling of resistance when inhaling and exhaling should be small.

The resistance for breathing that the diver feels will be points 2, 3-4, and 6 in the table.

First, the most important part is to reduce the negative pressure at point 2 in the table where the gas flow begins so that the diver can feel comfortable without feeling resistance. This work can be optimized by the person repairing the regulator.

How to set the cracking pressure to the best performance will be explained in detail in the next article.

Second, the pressure between points 3 and 4 in the table using the Venturi effect is where scuba instructors teach divers how to use it and where users can improve their breathing efforts while diving. Of course, a regulator without this function must continue to inhale air until the diver ends inhalation, and the pressure at points 4 and 5 in the table will also be different.

Third, point 6 in the table where the exhaled gas flow begins is already determined by the size, shape, and material of the exhaust diaphragm according to the regulator design, so it is not an area where the repairer can improve performance. Users simply need to maintain it well to prevent build-up of sticky substances or foreign substances to ensure maximum performance for which it is designed.

Lastly, the positive pressure from points 6 to 7 in the table varies depending on the diver’s breathing method and is largely unrelated to breathing resistance or breathing effort.

In conclusion, in order for a diver to breathe comfortably with a regulator, breathing effort should be reduced by lowering the cracking pressure where the air flow begins. Of course, freeflow should not occur even at the maximum intermediate pressure allowed by the manufacturer!